Optoelectronic Semiconductor

Detergents

Product features

- Several cleaning products exclusively designed for optoelectronic semiconductor.

- Water-based, dilutable formulation and easy rinsing without residue.

- Certified by US Sandia National Laboratory as the best alternative to Trichloroethylene (TCE).

- Non-corrosive and non-staining to a wide variety of metals and alloys (silicon, aluminum, copper, and titanium).

- removing various contaminants, shortening the process, and reducing the complicated solvent treatment. The chemicals required by the process can be simplified to a single product.

Free of VOCs, CFCs, Butyl, nPB, NMP and petroleum solvent; biologically degradable. Being used to replace acetone, NMP, MEK and IPA; conforming to RoHS and REACH ingredient standards; free of environmental hazardous substances. The environmentally friendly detergent you can trust.

Scope of Applications

- LED industry

- Solar industry

- Semiconductor industry

- Optical communication industry

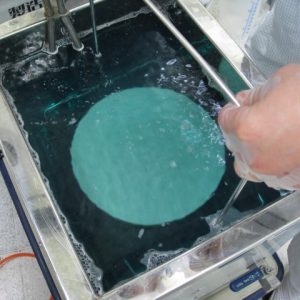

- Cleaning of LED, silicon wafer, and GaAs substrates

- Cleaning of epitaxial wafer

- Machining and cleaning of chip

- Photoresist removal and cleaning

- Cleaning after grinding and polishing

- Cleaning after cutting

- Cleaning of quartz jig

Types of contaminants which can be cleaned

Oily dirts

PARTICULATE DIRTS

powders after grinding and cutting….

Other contaminants

in addition to specific substances (process residues), there are protein contaminants, fungus, bacteria, and human finger marks….

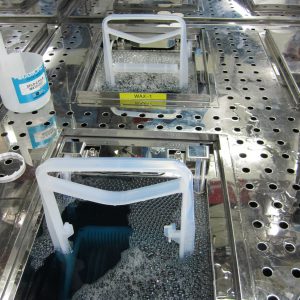

Cleaning approaches

There are high efficiency detergents of various properties to be used in coordination with different cleaning approaches.

Ultrasonic cleaning

Spray washing

Soaking

Manual wiping

•-Instagram-相片與影片.jpg)

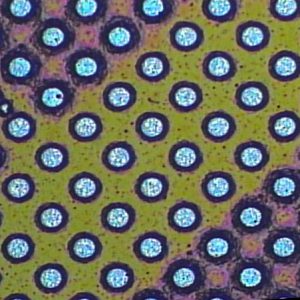

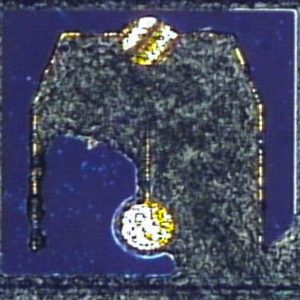

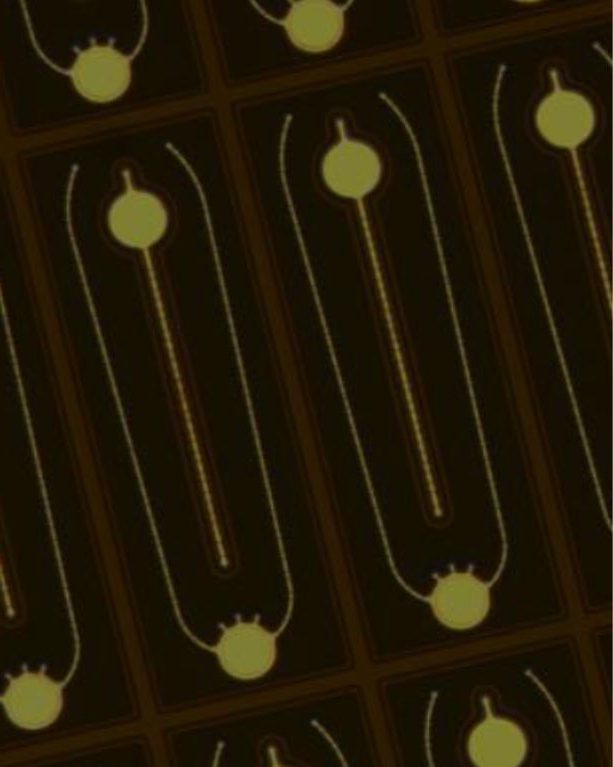

Figures of cleaning cases

Before

After

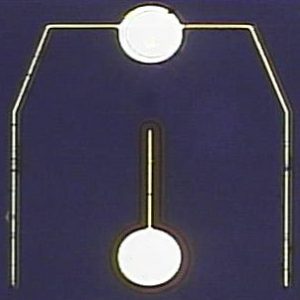

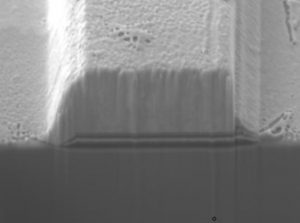

High Performance, Non-corrosive to Electrodes

The vigorous cleaning experiments have proven that they are not corrosive to N/P electrode.

•-Instagram-相片與影片.jpg)

test cleaning service

Cleaning Process

Key Guidance

Stage 1: Evaluation

You can discuss the material of object to be cleaned, type of contaminant, standard of cleanliness, condition of cleaning equipment, and impact on previous or next process for evaluation by phone call or in person.

Stage 2: Sample test cleaning

After confirmation of various conditions, we will provide professional judgment on the selection of detergent, conduct actual sample test, find out optimal cleaning conditions, parameters, and processes, and submit test report.

Stage 3: Actual test

We will provide samples to our customers for small-batch tests.

Stage 4: Joint development

When the test result does not reach the expected target, and both parties agree that it is necessary for our company to conduct the development of new detergent and conditions, they can sign the letter of intent for joint development.

•-Instagram-相片與影片.jpg)

FAQ

How often should we replace the detergent?

How to choose from various cleaning detergents?

First of all, detergents can be divided into aqueous detergent, CFC detergent, petroleum detergent, and hydrocarbon detergent. There are pros and cons of various detergents. The aqueous detergent is equipped with the advantages of low price, strong detergency, and environmental protection. The comprehensive adaptability is better than other types of detergents. The only disadvantage is that it will require drying after cleaning. Therefore, we Burlan will implement the concepts of environmental protection and health to recommend aqueous detergent to replace organic solvent as our effort in environmental protection.

Will you have the complete solution for the cleaning process?

Burlan is a professional environmentally friendly detergent provider in compliance with the environmental protection laws and regulations following the global trend. We are proficient in the cleaning processes of various industries. We can provide our customers with overall cleaning process guides to help them improve yields, increase production capacity, and save costs. Feel free to contact us directly if you have any question related to cleaning.

Is the quality of detergent stable?

The quality control of our product has always been our first priority. The incoming material and delivery of every batch of products will be inspected to ensure the stable quality. We will regularly track customers’ usage situations and obtain feedback in order to provide necessary assistance and to solve our customers’ problems.