Optics & electronic components

Detergents

Product features

- Ultra-powerful detergency; high permeability; quick and effective cleaning efficiency.

- Water-based, dilutable formulation making it easy to rinse after cleaning, so it will not affect subsequent machining of glass and quartz.

- Certified by US Sandia National Laboratory as the best alternative to Trichloroethylene (TCE).

- Non-corrosive to most substances (glass, quartz, plastic, aluminum, copper, and titanium), and also non-corrosive to most coatings such as IR, AR, AF, AS, etc.

- Removing various contaminants, shortening the process, and reducing the complicated solvent treatment. The chemicals required by the process can be simplified to a single product.

- Free of VOCs, CFCs, Butyl, nPB, NMP and petroleum solvent; biologically degradable. Being used to replace acetone, NMP, MEK and IPA; conforming to RoHS, REACH, and SONY_SS-00259 ingredient standards; free of environmental hazardous substances. The environmentally friendly detergent you can trust.

Scope of Applications

- LCD industry

- Quartz glass

- Molded glass

- Blue glass

- Optical coating

- Glass substrate cleaning

- Pre-ITO cleaning

- Cleaning of the entire LCD process

- Asphalt cleaning

- Cleaning of centering oil

- Cleaning before and after coating

- Optical coating deplating

Cleaning of coating chambers and jigs

•-Instagram-相片與影片.jpg)

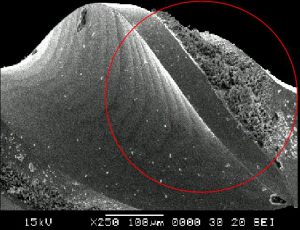

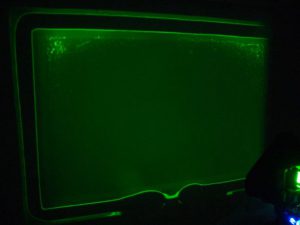

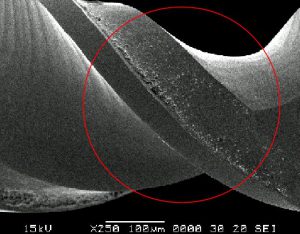

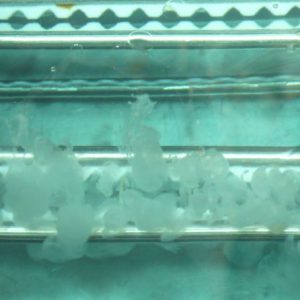

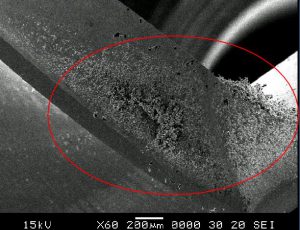

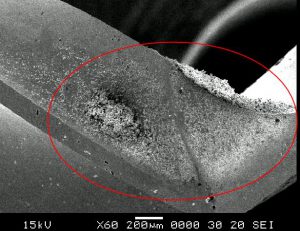

Figures of cleaning cases

Before

After

•-Instagram-相片與影片.jpg)

test cleaning service

Cleaning Process

Key Guidance

Stage 1: Evaluation

You can discuss the material of object to be cleaned, type of contaminant, standard of cleanliness, condition of cleaning equipment, and impact on previous or next process for evaluation by phone call or in person.

Stage 2: Sample test cleaning

After confirmation of various conditions, we will provide professional judgment on the selection of detergent, conduct actual sample test, find out optimal cleaning conditions, parameters, and processes, and submit test report.

Stage 3: Actual test

We will provide samples to our customers for small-batch tests.

Stage 4: Joint development

When the test result does not reach the expected target, and both parties agree that it is necessary for our company to conduct the development of new detergent and conditions, they can sign the letter of intent for joint development.